| Deploy |

Alternative Insulation Materials |

256Highly Recommended

|

Cut Emissions |

152

Industry, Materials & Waste |

Improve Materials |

insulation units of 100 m² and 1 m²·K/W |

1.59 |

1.4×10⁷/yr |

2.9×10⁷ to 7.3×10⁷/yr |

0.05 to 0.12 |

-121.00

|

CO₂,

F-gas |

195Emergency Brake |

|

| Deploy |

Alternative Refrigerants |

256Highly Recommended

|

Cut Emissions |

152

Industry, Materials & Waste |

Improve Materials |

kt high-GWP refrigerant phased out |

460,000/yr |

440 |

5,500 to 5,900 |

2.50 to 2.70 |

50.00

|

F-gases |

195Emergency Brake |

|

| Improve |

Annual Cropping |

256Highly Recommended

|

Cut Emissions, Remove Carbon |

156

FALO & Nature-Based Carbon Removal |

Shift Agriculture Practices |

ha cropland |

1.8/yr |

2.674×10⁸ |

3.317×10⁸ to 7.0×10⁸ |

0.43 to 1.09 |

47.80

|

CO₂, N₂O |

197Delayed |

|

| Increase |

Carpooling |

256Highly Recommended

|

Cut Emissions |

153

Transportation |

Shift to Alternatives |

million pkm avoided |

54.71 |

0/yr |

4.638×10⁶ to 1.752×10⁷/yr |

0.25 to 0.96 |

-3119.00

|

CO₂

, CH₄, N₂O, BC |

196Gradual |

|

| Improve |

Cement Production: Clinker substitution |

256Highly Recommended

|

Cut Emissions |

152

Industry, Materials & Waste |

Improve Materials |

Mt clinker avoided |

690,000 |

980/yr |

1,000 to 2,000/yr |

0.70 to 1.00 |

-30.00

|

CO₂

|

196Gradual |

|

| Improve |

Cement Production: Alternative fuels |

256Highly Recommended

|

Cut Emissions |

152

Industry, Materials & Waste |

Improve Materials |

Mt cement produced using alternative fuels |

96,000 |

300/yr |

610 to 2,000/yr |

0.06 to 0.20 |

-50.00

|

CO₂

|

196Gradual |

|

| Improve |

Cement Production: Efficiency upgrades |

256Highly Recommended

|

Cut Emissions |

152

Industry, Materials & Waste |

Improve Materials |

GJ thermal energy input reduced from current levels/yr |

0.085 |

0/yr |

8.86×10⁸ to 1.18×10⁹/yr |

0.08 to 0.10 |

-60.00

|

CO₂

|

196Gradual |

|

| Increase |

Centralized Composting |

256Highly Recommended

|

Cut Emissions |

152

Industry, Materials & Waste |

Use Waste as a Resource |

t organic waste |

3.9 |

7.8×10⁷/yr |

2.009×10⁸ to 3.01×10⁸/yr |

0.78 to 1.20 |

10.00

|

CO₂,

CH₄

|

195Emergency Brake |

|

| Deploy |

Clean Cooking |

256Highly Recommended

|

Cut Emissions |

148

Buildings |

Shift Energy Sources |

household switching to cleaner cooking |

2.3/yr |

|

4.2×10⁸ to 4.2×10⁸ |

0.98 to 0.98 |

27.00

|

CO₂, CH₄,

BC |

195Emergency Brake |

|

| Manage |

Coal Mine Methane |

256Highly Recommended

|

Cut Emissions |

154

Other Energy |

Cut Fugitive Emissions |

Mt methane abated |

2.79×10⁷ |

0.59/yr |

2.83 to 4.4/yr |

0.08 to 0.12 |

-3.17

|

CH₄

, N₂O, BC |

195Emergency Brake |

|

| Protect |

Coastal Wetlands: Mangrove ecosystems |

256Highly Recommended

|

Cut Emissions |

156

FALO & Nature-Based Carbon Removal |

Protect & Manage Ecosystems |

ha protected |

7.88/yr |

2.94×10⁶ |

7.85×10⁶ to 1.1×10⁷ |

0.06 to 0.09 |

1.00

|

CO₂

|

195Emergency Brake |

|

| Protect |

Coastal Wetlands: Salt marsh ecosystems |

WorthwhileWorthwhile

|

Cut Emissions |

156

FALO & Nature-Based Carbon Removal |

Protect & Manage Ecosystems |

ha protected |

4.78/yr |

1.24×10⁶ |

3.75×10⁶ to 5.25×10⁶ |

0.02 to 0.03 |

2.00

|

CO₂

|

195Emergency Brake |

|

| Protect |

Coastal Wetlands: Seagrass ecosystems |

256Highly Recommended

|

Cut Emissions |

156

FALO & Nature-Based Carbon Removal |

Protect & Manage Ecosystems |

ha protected |

3.56/yr |

3.86×10⁶ |

1.57×10⁷ to 2.2×10⁷ |

0.06 to 0.08 |

-6.00

|

CO₂

|

195Emergency Brake |

|

| Improve |

Diets |

256Highly Recommended

|

Cut Emissions |

155

Food, Agriculture, Land & Ocean (FALO) |

Curb Growing Demands |

kg avoided ruminant meat |

0.065 |

0/yr |

2.14×10¹⁰ to 4.29×10¹⁰/yr |

1.40 to 2.80 |

-8.54

|

CO₂,

CH₄

, N₂O

|

195Emergency Brake |

|

| Mobilize |

Electric Bicycles: Private electric bicycles |

256Highly Recommended

|

Cut Emissions |

153

Transportation |

Electrify Vehicles |

1,000 electric bicycles |

110.5/yr |

277,600 |

421,300 to 1.01×10⁶ |

0.05 to 0.11 |

-1748.00

|

CO₂, CH₄, N₂O, BC |

196Gradual |

|

| Mobilize |

Electric Bicycles: Shared electric bicycles |

WorthwhileWorthwhile

|

Cut Emissions |

153

Transportation |

Electrify Vehicles |

1,000 electric bicycles |

14.44/yr |

2,000 |

22,010 to 69,260 |

0.00 to 0.00 |

22860.00

|

CO₂, CH₄, N₂O, BC |

196Gradual |

|

| Mobilize |

Electric Cars |

256Highly Recommended

|

Cut Emissions |

153

Transportation |

Electrify Vehicles |

million passenger kilometers (million pkm) |

48.52 |

818,900/yr |

2.602×10⁷ to 4.731×10⁷/yr |

1.26 to 2.30 |

-1019.00

|

CO₂, CH₄, N₂O, BC |

196Gradual |

|

| Reduce |

Food Loss & Waste |

256Highly Recommended

|

Cut Emissions |

155

Food, Agriculture, Land & Ocean (FALO) |

Curb Growing Demands |

t reduced FLW |

2.82 |

|

4.375×10⁸ to 8.75×10⁸/yr |

1.23 to 2.47 |

-193.99

|

CO₂

, CH₄

, N₂O

|

195Emergency Brake |

|

| Protect |

Forests: Boreal |

256Highly Recommended

|

Cut Emissions, Remove Carbon |

156

FALO & Nature-Based Carbon Removal |

Protect & Manage Ecosystems |

ha protected |

0.299/yr |

4.67×10⁸ |

8.47×10⁸ to 8.61×10⁸ |

0.25 to 0.26 |

2.00

|

CO₂ |

195Emergency Brake |

|

| Restore |

Forests: Boreal |

256Highly Recommended

|

Remove Carbon |

157

Nature-Based Carbon Removal |

Restore & Manage Ecosystems |

ha under restoration |

10.21/yr |

|

9.7×10⁶ to 1.46×10⁷ |

0.10 to 0.15 |

53.00

|

CO₂

|

197Delayed |

|

| Protect |

Forests: Temperate |

256Highly Recommended

|

Cut Emissions, Remove Carbon |

156

FALO & Nature-Based Carbon Removal |

Protect & Manage Ecosystems |

ha protected |

1.403/yr |

1.59×10⁸ |

2.04×10⁸ to 3.78×10⁸ |

0.29 to 0.53 |

2.00

|

CO₂ |

195Emergency Brake |

|

| Restore |

Forests: Temperate |

256Highly Recommended

|

Remove Carbon |

157

Nature-Based Carbon Removal |

Restore & Manage Ecosystems |

ha under restoration |

12.11/yr |

|

9.5×10⁶ to 1.43×10⁷ |

0.12 to 0.17 |

53.00

|

CO₂

|

197Delayed |

|

| Restore |

Forests: Subtropical |

256Highly Recommended

|

Remove Carbon |

157

Nature-Based Carbon Removal |

Restore & Manage Ecosystems |

ha under restoration |

11.78/yr |

|

1.7×10⁶ to 2.6×10⁶ |

0.02 to 0.03 |

53.00

|

CO₂

|

197Delayed |

|

| Protect |

Forests: Subtropical |

256Highly Recommended

|

Cut Emissions, Remove Carbon |

156

FALO & Nature-Based Carbon Removal |

Protect & Manage Ecosystems |

ha protected |

2.204/yr |

1.12×10⁸ |

1.26×10⁸ to 2.19×10⁸ |

0.28 to 0.48 |

2.00

|

CO₂ |

195Emergency Brake |

|

| Restore |

Forests: Tropical |

256Highly Recommended

|

Remove Carbon |

157

Nature-Based Carbon Removal |

Restore & Manage Ecosystems |

ha under restoration |

17.63/yr |

|

2.74×10⁷ to 4.11×10⁷ |

0.48 to 0.73 |

53.00

|

CO₂

|

197Delayed |

|

| Protect |

Forests: Tropical |

256Highly Recommended

|

Cut Emissions, Remove Carbon |

156

FALO & Nature-Based Carbon Removal |

Protect & Manage Ecosystems |

ha protected |

1.489/yr |

9.36×10⁸ |

1.12×10⁹ to 1.577×10⁹ |

1.67 to 2.35 |

2.00

|

CO₂ |

195Emergency Brake |

|

| Protect |

Grasslands & Savannas: Boreal |

256Highly Recommended

|

Cut Emissions and Remove Carbon |

156

FALO & Nature-Based Carbon Removal |

Protect & Manage Ecosystems |

ha of grassland or savanna protected |

0.9/yr |

3.386×10⁸ |

3.386×10⁸ to 3.731×10⁸ |

0.31 to 0.34 |

-1.58

|

CO₂,

N₂O

|

195Emergency Brake |

|

| Protect |

Grasslands & Savannas: Temperate |

256Highly Recommended

|

Cut Emissions and Remove Carbon |

156

FALO & Nature-Based Carbon Removal |

Protect & Manage Ecosystems |

ha of grassland or savanna protected |

0.54/yr |

1.722×10⁸ |

3.617×10⁸ to 5.064×10⁸ |

0.20 to 0.27 |

-1.58

|

CO₂,

N₂O

|

195Emergency Brake |

|

| Protect |

Grasslands & Savannas: Subtropical |

256Highly Recommended

|

Cut Emissions and Remove Carbon |

156

FALO & Nature-Based Carbon Removal |

Protect & Manage Ecosystems |

ha of grassland or savanna protected |

0.13/yr |

2.93×10⁸ |

3.132×10⁸ to 4.385×10⁸ |

0.04 to 0.06 |

-1.58

|

CO₂,

N₂O

|

195Emergency Brake |

|

| Protect |

Grasslands & Savannas: Tropical |

256Highly Recommended

|

Cut Emissions and Remove Carbon |

156

FALO & Nature-Based Carbon Removal |

Protect & Manage Ecosystems |

ha of grassland or savanna protected |

0.06/yr |

5.826×10⁸ |

5.826×10⁸ to 7.059×10⁸ |

0.03 to 0.04 |

-1.58

|

CO₂,

N₂O

|

195Emergency Brake |

|

| Use |

Heat Pumps |

256Highly Recommended

|

Cut Emissions |

149

Buildings & Electricity |

Enhance Efficiency, Shift Energy Sources |

heat pump systems |

0.95/yr |

1.3×10⁸ |

6.0×10⁸ to 9.6×10⁸ |

0.57 to 0.91 |

-200.00

|

CO₂

, CH₄, N₂O, BC |

196Gradual |

|

| Mobilize |

Hybrid Cars |

256Highly Recommended

|

Cut Emissions |

153

Transportation |

Enhance Efficiency |

million passenger kilometers (million pkm) |

27.11 |

1.318×10⁶/yr |

1.183×10⁷ to 2.957×10⁷/yr |

0.32 to 0.80 |

264.00

|

CO₂

, CH₄, N₂O, BC |

196Gradual |

|

| Improve |

Landfill Management: Methane capture |

256Highly Recommended

|

Cut Emissions |

152

Industry, Materials & Waste |

Cut Fugitive Emissions |

Mt methane abated |

2.79×10⁷ |

1.59/yr |

4.5 to 34.78/yr |

0.13 to 0.97 |

-6.42

|

CH₄, N₂O, BC |

195Emergency Brake |

|

| Improve |

Landfill Management: Biocovers |

256Highly Recommended

|

Cut Emissions |

152

Industry, Materials & Waste |

Cut Fugitive Emissions |

Mt methane abated |

2.79×10⁷ |

0/yr |

35.13 to 57.04/yr |

0.98 to 1.59 |

0.47

|

CH₄, N₂O, BC |

195Emergency Brake |

|

| Deploy |

LED Lighting |

256Highly Recommended

|

Cut Emissions |

150

Electricity |

Enhance Efficiency |

% lamps LED |

7.09×10⁶/yr |

50.5 |

87 to 92 |

0.62 to 0.65 |

-175.00

|

CO₂, CH₄, N₂O, BC |

196Gradual |

|

| Improve |

Nonmotorized Transportation |

256Highly Recommended

|

Cut Emissions |

153

Transportation |

Shift to Alternatives |

million passenger kilometers (million pkm) |

115.6 |

5.556×10⁶/yr |

1.236×10⁷ to 1.634×10⁷/yr |

1.43 to 1.89 |

-1771.00

|

CO₂, CH₄, N₂O, BC |

196Gradual |

|

| Improve |

Nutrient Management |

256Highly Recommended

|

Cut Emissions |

155

Food, Agriculture, Land & Ocean (FALO) |

Shift Agriculture Practices |

t avoided excess nitrogen application |

6 |

1.045×10⁷/yr |

6.985×10⁷ to 9.106×10⁷/yr |

0.42 to 0.54 |

-85.21

|

N₂O |

196Gradual |

|

| Deploy |

Offshore Wind Turbines |

256Highly Recommended

|

Cut Emissions |

150

Electricity |

Shift Production |

MW installed capacity |

1,900/yr |

73,000 |

1.0×10⁶ to 1.6×10⁶ |

1.90 to 3.04 |

|

CO₂

, CH₄, N₂O, BC |

196Gradual |

|

| Manage |

Oil & Gas Methane |

256Highly Recommended

|

Cut Emissions |

154

Other Energy |

Cut Fugitive Emissions |

Mt methane abated |

2.79×10⁷ |

|

3.26 to 8.84/yr |

0.09 to 0.25 |

-6.20

|

CH₄, N₂O, BC |

195Emergency Brake |

|

| Deploy |

Onshore Wind Turbines |

256Highly Recommended

|

Cut Emissions |

150

Electricity |

Shift Production |

MW installed capacity |

1,700/yr |

940,000 |

3.2×10⁶ to 4.4×10⁶ |

5.40 to 7.50 |

|

CO₂

, CH₄, N₂O, BC |

196Gradual |

|

| Protect |

Peatlands: Boreal |

256Highly Recommended

|

Cut Emissions and Remove Carbon |

156

FALO & Nature-Based Carbon Removal |

Protect & Manage Ecosystems |

ha protected |

0.92/yr |

5.4×10⁷ |

1.99×10⁸ to 2.55×10⁸ |

0.18 to 0.24 |

0.25

|

CO₂

, CH₄, N₂O

|

195Emergency Brake |

|

| Protect |

Peatlands: Temperate |

256Highly Recommended

|

Cut Emissions and Remove Carbon |

156

FALO & Nature-Based Carbon Removal |

Protect & Manage Ecosystems |

ha protected |

4.42/yr |

1.3×10⁷ |

1.8×10⁷ to 2.4×10⁷ |

0.08 to 0.11 |

0.25

|

CO₂

, CH₄, N₂O

|

195Emergency Brake |

|

| Protect |

Peatlands: Subtropical |

256Highly Recommended

|

Cut Emissions and Remove Carbon |

156

FALO & Nature-Based Carbon Removal |

Protect & Manage Ecosystems |

ha protected |

13.47/yr |

3.0×10⁶ |

9.0×10⁶ to 1.1×10⁷ |

0.12 to 0.15 |

0.25

|

CO₂

, CH₄, N₂O

|

195Emergency Brake |

|

| Protect |

Peatlands: Tropical |

256Highly Recommended

|

Cut Emissions and Remove Carbon |

156

FALO & Nature-Based Carbon Removal |

Protect & Manage Ecosystems |

ha protected |

13.23/yr |

3.5×10⁷ |

7.2×10⁷ to 9.2×10⁷ |

0.95 to 1.22 |

0.25

|

CO₂

, CH₄, N₂O

|

195Emergency Brake |

|

| Enhance |

Public Transit |

256Highly Recommended

|

Cut Emissions |

153

Transportation |

Shift to Alternatives |

million passenger kilometers (million pkm) |

58.27 |

6.784×10⁶/yr |

1.203×10⁷ to 1.767×10⁷/yr |

0.70 to 1.03 |

-3300.00

|

CO₂, CH₄, N₂O, BC |

196Gradual |

|

| Increase |

Recycling: Metals |

256Highly Recommended

|

Cut Emissions |

152

Industry, Materials & Waste |

Use Waste as a Resource |

Mt recycled |

1.48×10⁶ |

740/yr |

1,300 to 1,400/yr |

1.90 to 2.10 |

-100.00

|

CO₂

, CH₄

|

196Gradual |

|

| Increase |

Recycling: Paper and Cardboard |

256Highly Recommended

|

Cut Emissions |

152

Industry, Materials & Waste |

Use Waste as a Resource |

Mt recycled |

1.0×10⁶ |

160/yr |

220 to 260/yr |

0.22 to 0.26 |

-400.00

|

CO₂

, CH₄

|

196Gradual |

|

| Increase |

Recycling: Plastics |

256Highly Recommended

|

Cut Emissions |

152

Industry, Materials & Waste |

Use Waste as a Resource |

Mt recycled |

2.0×10⁶ |

35.9/yr |

45 to 54/yr |

0.09 to 0.10 |

-4.00

|

CO₂

, CH₄

|

196Gradual |

|

| Increase |

Recycling: Glass |

WorthwhileWorthwhile

|

Cut Emissions |

152

Industry, Materials & Waste |

Use Waste as a Resource |

Mt recycled |

79,000 |

27/yr |

36 to 48/yr |

0.00 to 0.00 |

9000.00

|

CO₂

, CH₄

|

196Gradual |

|

| Improve |

Rice Production |

256Highly Recommended

|

Cut Emissions |

155

Food, Agriculture, Land & Ocean (FALO) |

Shift Agriculture Practices |

ha rice paddies |

2.03/yr |

4.865×10⁷ |

4.956×10⁷ to 7.753×10⁷ |

0.10 to 0.16 |

-175.00

|

CH₄

, N₂O

|

195Emergency Brake |

|

| Deploy |

Silvopasture |

256Highly Recommended

|

Remove Carbon |

157

Nature-Based Carbon Removal |

Shift Agriculture Practices |

ha converted from grazing land to silvopasture |

9.81/yr |

1.414×10⁸ |

1.47×10⁸ to 2.063×10⁸ |

0.40 to 0.98 |

43.25

|

CO₂

|

197Delayed |

|

| Improve |

Windows & Glass |

256Highly Recommended

|

Cut Emissions |

149

Buildings & Electricity |

Enhance Efficiency |

m2 windows minimum double-glazed |

0.065/yr |

1.99×10¹⁰ |

3.29×10¹⁰ to 4.0×10¹⁰ |

2.10 to 2.60 |

-123.00

|

CO₂

, CH₄, N₂O, BC |

196Gradual |

|

| Boost |

Appliance & Equipment Efficiency |

257Worthwhile

|

Cut Emissions |

149

Buildings & Electricity |

Enhance Efficiency |

— |

|

|

|

|

|

|

|

|

| Improve |

Aquaculture |

257Worthwhile

|

Cut Emissions |

155

Food, Agriculture, Land & Ocean (FALO) |

Shift Agriculture Practices |

— |

|

|

|

|

|

|

|

|

| Deploy |

Electric Irrigation Pumps |

257Worthwhile

|

Cut Emissions |

155

Food, Agriculture, Land & Ocean (FALO) |

Fuel Switching |

— |

|

|

|

|

|

|

|

|

| Improve |

Fishing Vessel Efficiency |

257Worthwhile

|

Cut Emissions |

153

Transportation |

Enhance Efficiency |

— |

|

|

|

|

|

|

|

|

| Use |

Low-Flow Fixtures |

257Worthwhile

|

Cut Emissions |

149

Buildings & Electricity |

Enhance Efficiency |

— |

|

|

|

|

|

|

|

|

| Improve |

Manure Management |

257Worthwhile

|

Cut Emissions |

155

Food, Agriculture, Land & Ocean (FALO) |

Shift Agriculture Practices |

— |

|

|

|

|

|

|

|

|

| Reduce |

Overfishing |

257Worthwhile

|

Cut Emissions |

155

Food, Agriculture, Land & Ocean (FALO) |

Restore & Manage Ecosystems |

— |

|

|

|

|

|

|

|

|

| Deploy |

Advanced Geothermal Energy |

258Keep Watching

|

Cut Emissions |

150

Electricity |

Shift Production |

— |

|

|

|

|

|

|

|

|

| Reduce |

Airplane Contrails |

258Keep Watching

|

Other |

153

Transportation |

Solar Radiation Management |

— |

|

|

|

|

|

|

|

|

| Advance |

Cultivated Meat |

258Keep Watching

|

Cut Emissions |

155

Food, Agriculture, Land & Ocean (FALO) |

Curb Growing Demands |

— |

|

|

|

|

|

|

|

|

| Deploy |

District Cooling |

258Keep Watching

|

Cut Emissions |

150

Electricity |

Enhance Efficiency |

— |

|

|

|

|

|

|

|

|

| Improve |

District Heating: Industry |

258Keep Watching

|

Cut Emissions |

152

Industry, Materials & Waste |

Shift Energy Sources |

— |

|

|

|

|

|

|

|

|

| Deploy |

Enhanced Rock Weathering |

258Keep Watching

|

Remove Carbon |

157

Nature-Based Carbon Removal |

Manipulate Biogeochemical Cycles |

— |

|

|

|

|

|

|

|

|

| Use |

Feed Additives |

258Keep Watching

|

Cut Emissions |

155

Food, Agriculture, Land & Ocean (FALO) |

Shift Agriculture Practices |

— |

|

|

|

|

|

|

|

|

| Mobilize |

Green Hydrogen for Aviation and Trucking |

258Keep Watching

|

Cut Emissions |

153

Transportation |

Fuel Switching |

— |

|

|

|

|

|

|

|

|

| Improve |

Irrigation Water Use Efficiency |

258Keep Watching

|

Cut Emissions |

155

Food, Agriculture, Land & Ocean (FALO) |

Shift Agriculture Practices |

— |

|

|

|

|

|

|

|

|

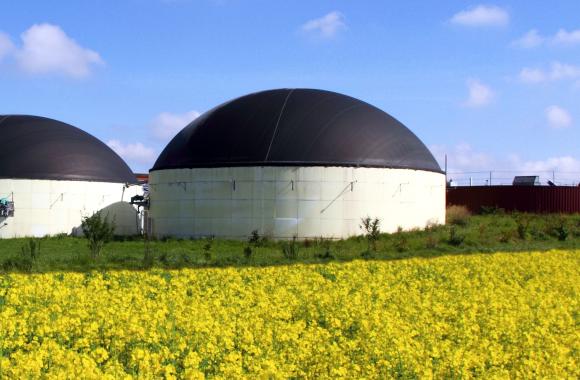

| Deploy |

Methane Digesters |

258Keep Watching

|

Cut Emissions |

152

Industry, Materials & Waste |

Use Waste as a Resource |

— |

|

|

|

|

|

|

|

|

| Deploy |

Micro Wind Turbines |

258Keep Watching

|

Cut Emissions |

150

Electricity |

Shift Production |

— |

|

|

|

|

|

|

|

|

| Deploy |

Nuclear Fusion |

258Keep Watching

|

Cut Emissions |

150

Electricity |

Shift Production |

— |

|

|

|

|

|

|

|

|

| Deploy |

Ocean Alkalinity Enhancement |

258Keep Watching

|

Remove Carbon |

157

Nature-Based Carbon Removal |

Manipulate Biogeochemical Cycles |

— |

|

|

|

|

|

|

|

|

| Deploy |

Plastic Alternatives / Bioplastics |

258Keep Watching

|

Cut Emissions |

152

Industry, Materials & Waste |

Improve Materials |

— |

|

|

|

|

|

|

|

|

| Improve |

Ruminant Breeding |

258Keep Watching

|

Cut Emissions |

155

Food, Agriculture, Land & Ocean (FALO) |

Shift Agriculture Practices |

— |

|

|

|

|

|

|

|

|

| Protect |

Seafloors |

258Keep Watching

|

Cut Emissions and Remove Carbon |

155

Food, Agriculture, Land & Ocean (FALO) |

Protect & Manage Ecosystems |

— |

|

|

|

|

|

|

|

|

| Restore |

Seaweed Ecosystems |

258Keep Watching

|

Remove Carbon |

157

Nature-Based Carbon Removal |

Restore & Manage Ecosystems |

— |

|

|

|

|

|

|

|

|

| Deploy |

Seaweed Farming for Food |

258Keep Watching

|

Cut Emissions |

155

Food, Agriculture, Land & Ocean (FALO) |

Curb Growing Demands |

— |

|

|

|

|

|

|

|

|

| Deploy |

Small Modular Nuclear Reactors |

258Keep Watching

|

Cut Emissions |

150

Electricity |

Shift Production |

— |

|

|

|

|

|

|

|

|

| Improve |

Steel Production |

258Keep Watching

|

Cut Emissions |

152

Industry, Materials & Waste |

Improve Materials, Shift Energy Sources |

— |

|

|

|

|

|

|

|

|

| Produce |

Blue Hydrogen |

259Not Recommended

|

Cut Emissions |

152

Industry, Materials & Waste |

Improve Processes |

— |

|

|

|

|

|

|

|

|

| Use |

Carbon Capture & Storage on Fossil Fuel Power Plants |

259Not Recommended

|

Cut Emissions |

150

Electricity |

Shift Production |

— |

|

|

|

|

|

|

|

|

| Use |

Corn Ethanol |

259Not Recommended

|

Cut Emissions |

153

Transportation |

Fuel Switching |

— |

|

|

|

|

|

|

|

|

| Deploy |

Direct Air Capture |

259Not Recommended

|

Remove Carbon |

158

Industrial Carbon Removal |

Carbon Removal & Storage |

— |

|

|

|

|

|

|

|

|

| Deploy |

Insect Farming for Food and Feed |

259Not Recommended

|

Cut Emissions |

155

Food, Agriculture, Land & Ocean (FALO) |

Curb Growing Demands |

— |

|

|

|

|

|

|

|

|

| Deploy |

Ocean Biomass Sinking |

259Not Recommended

|

Cut Emissions and Remove Carbon, Remove Carbon |

157

Nature-Based Carbon Removal |

Biomass Carbon Removal & Storage |

— |

|

|

|

|

|

|

|

|

| Deploy |

Ocean Fertilization |

259Not Recommended

|

Remove Carbon |

157

Nature-Based Carbon Removal |

Manipulate Biogeochemical Cycles |

— |

|

|

|

|

|

|

|

|

| Deploy |

Stratospheric Aerosol Injection |

259Not Recommended

|

Other |

263

Geoengineering |

Solar Radiation Management |

— |

|

|

|

|

|

|

|

|

| Deploy |

Vertical Farms |

259Not Recommended

|

Cut Emissions |

155

Food, Agriculture, Land & Ocean (FALO) |

Shift Agriculture Practices |

— |

|

|

|

|

|

|

|

|

| Restore |

Abandoned Farmland |

256Highly Recommended

|

Remove Carbon |

157

Nature-Based Carbon Removal |

Use Degraded Land |

Coming Soon |

|

|

|

|

|

|

|

|

| Deploy |

Agrivoltaics |

256Highly Recommended

|

Cut Emissions |

150

Electricity |

Shift Production |

Coming Soon |

|

|

|

|

|

|

|

|

| Deploy |

Agroforestry: Trees on Cropland |

256Highly Recommended

|

Remove Carbon |

157

Nature-Based Carbon Removal |

Shift Agriculture Practices |

Coming Soon |

|

|

|

|

|

|

|

|

| Deploy |

Agroforestry: Multi-strata |

256Highly Recommended

|

Remove Carbon |

157

Nature-Based Carbon Removal |

Shift Agriculture Practices |

Coming Soon |

|

|

|

|

|

|

|

|

| Improve |

Aviation Efficiency |

256Highly Recommended

|

Cut Emissions |

153

Transportation |

Enhance Efficiency |

Coming Soon |

|

|

|

|

|

|

|

|

| Produce |

Biochar |

256Highly Recommended

|

Remove Carbon |

158

Industrial Carbon Removal |

Biomass Carbon Removal & Storage |

Coming Soon |

|

|

|

|

|

|

|

|

| Deploy |

Bioelectricity with Carbon Capture & Storage |

256Highly Recommended

|

Cut Emissions |

151

Electricity & Industry |

Shift Production |

Coming Soon |

|

|

|

|

|

|

|

|

| Deploy |

Biomass Crops on Degraded Land |

256Highly Recommended

|

Remove Carbon |

157

Nature-Based Carbon Removal |

Use Degraded Land |

Coming Soon |

|

|

|

|

|

|

|

|

| Improve |

Building Envelopes |

256Highly Recommended

|

Cut Emissions |

149

Buildings & Electricity |

Enhance Efficiency |

Coming Soon |

|

|

|

|

|

|

|

|

| Automate |

Building Systems |

256Highly Recommended

|

Cut Emissions |

149

Buildings & Electricity |

Enhance Efficiency |

Coming Soon |

|

|

|

|

|

|

|

|

| Deploy |

Concentrated Solar |

256Highly Recommended

|

Cut Emissions |

150

Electricity |

Shift Production |

Coming Soon |

|

|

|

|

|

|

|

|

| Reduce |

Crop Residue Burning |

256Highly Recommended

|

Cut Emissions |

155

Food, Agriculture, Land & Ocean (FALO) |

Shift Agriculture Practices |

Coming Soon |

|

|

|

|

|

|

|

|

| Use |

Direct Air Capture Methane |

256Highly Recommended

|

Remove Carbon |

158

Industrial Carbon Removal |

Carbon Removal & Storage |

Coming Soon |

|

|

|

|

|

|

|

|

| Deploy |

Distributed Solar PV |

256Highly Recommended

|

Cut Emissions |

150

Electricity |

Shift Production |

Coming Soon |

|

|

|

|

|

|

|

|

| Improve |

District Heating: Buildings |

256Highly Recommended

|

Cut Emissions |

149

Buildings & Electricity |

Enhance Efficiency |

Coming Soon |

|

|

|

|

|

|

|

|

| Mobilize |

Electric Scooters & Motorcycles |

256Highly Recommended

|

Cut Emissions |

153

Transportation |

Electrify Vehicles, Fuel Switching |

Coming Soon |

|

|

|

|

|

|

|

|

| Mobilize |

Electric Trains |

256Highly Recommended

|

Cut Emissions |

153

Transportation |

Electrify Vehicles, Fuel Switching |

Coming Soon |

|

|

|

|

|

|

|

|

| Mobilize |

Electric Trucks & Buses |

256Highly Recommended

|

Cut Emissions |

153

Transportation |

Electrify Vehicles, Fuel Switching |

Coming Soon |

|

|

|

|

|

|

|

|

| Support |

Family Planning & Education |

256Highly Recommended

|

Society |

159

Health & Education |

|

Coming Soon |

|

|

|

|

|

|

|

|

| Improve |

Forest Management: Sustainable Forest Management |

256Highly Recommended

|

Cut Emissions |

155

Food, Agriculture, Land & Ocean (FALO) |

Protect & Manage Ecosystems |

Coming Soon |

|

|

|

|

|

|

|

|

| Improve |

Forest Management: Integrated Fire Management |

256Highly Recommended

|

Cut Emissions |

155

Food, Agriculture, Land & Ocean (FALO) |

Protect & Manage Ecosystems |

Coming Soon |

|

|

|

|

|

|

|

|

| Deploy |

Geothermal Power |

256Highly Recommended

|

Cut Emissions |

150

Electricity |

Shift Production |

Coming Soon |

|

|

|

|

|

|

|

|

| Restore |

Grasslands & Savannas: Boreal |

256Highly Recommended

|

Remove Carbon |

157

Nature-Based Carbon Removal |

Restore & Manage Ecosystems |

Coming Soon |

|

|

|

|

|

|

|

|

| Restore |

Grasslands & Savannas: Temperate |

256Highly Recommended

|

Remove Carbon |

157

Nature-Based Carbon Removal |

Restore & Manage Ecosystems |

Coming Soon |

|

|

|

|

|

|

|

|

| Restore |

Grasslands & Savannas: Subtropical |

256Highly Recommended

|

Remove Carbon |

157

Nature-Based Carbon Removal |

Restore & Manage Ecosystems |

Coming Soon |

|

|

|

|

|

|

|

|

| Restore |

Grasslands & Savannas: Tropical |

256Highly Recommended

|

Remove Carbon |

157

Nature-Based Carbon Removal |

Restore & Manage Ecosystems |

Coming Soon |

|

|

|

|

|

|

|

|

| Increase |

Green Roofs & Urban Greenspace |

256Highly Recommended

|

Cut Emissions |

149

Buildings & Electricity |

Enhance Efficiency |

Coming Soon |

|

|

|

|

|

|

|

|

| Improve |

Grid Efficiency |

256Highly Recommended

|

Cut Emissions |

150

Electricity |

Improve Electrical System |

Coming Soon |

|

|

|

|

|

|

|

|

| Enhance |

High-Speed Rail |

256Highly Recommended

|

Cut Emissions |

153

Transportation |

Shift to Alternatives |

Coming Soon |

|

|

|

|

|

|

|

|

| Boost |

Industrial Efficiency |

256Highly Recommended

|

Cut Emissions |

151

Electricity & Industry |

Enhance Efficiency |

Coming Soon |

|

|

|

|

|

|

|

|

| Increase |

Industrial Electrification |

256Highly Recommended

|

Cut Emissions |

152

Industry, Materials & Waste |

Improve Processes |

Coming Soon |

|

|

|

|

|

|

|

|

| Deploy |

Industrial Green Hydrogen |

256Highly Recommended

|

Cut Emissions |

152

Industry, Materials & Waste |

Improve Processes |

Coming Soon |

|

|

|

|

|

|

|

|

| Improve |

Livestock Grazing |

256Highly Recommended

|

Remove Carbon |

157

Nature-Based Carbon Removal |

Shift Agriculture Practices |

Coming Soon |

|

|

|

|

|

|

|

|

| Deploy |

Low-Emission Industrial Feedstocks |

256Highly Recommended

|

Cut Emissions |

152

Industry, Materials & Waste |

Improve Materials |

Coming Soon |

|

|

|

|

|

|

|

|

| Deploy |

Nuclear Power |

256Highly Recommended

|

Cut Emissions |

150

Electricity |

Shift Production |

Coming Soon |

|

|

|

|

|

|

|

|

| Improve |

Ocean Shipping Efficiency |

256Highly Recommended

|

Cut Emissions |

153

Transportation |

Enhance Efficiency |

Coming Soon |

|

|

|

|

|

|

|

|

| Improve |

Other Building Materials |

256Highly Recommended

|

Cut Emissions |

152

Industry, Materials & Waste |

Improve Materials |

Coming Soon |

|

|

|

|

|

|

|

|

| Restore |

Peatlands: Boreal |

256Highly Recommended

|

Remove Carbon |

157

Nature-Based Carbon Removal |

Restore & Manage Ecosystems |

Coming Soon |

|

|

|

|

|

|

|

|

| Restore |

Peatlands: Temperate |

256Highly Recommended

|

Remove Carbon |

157

Nature-Based Carbon Removal |

Restore & Manage Ecosystems |

Coming Soon |

|

|

|

|

|

|

|

|

| Restore |

Peatlands: Subtropical |

256Highly Recommended

|

Remove Carbon |

157

Nature-Based Carbon Removal |

Restore & Manage Ecosystems |

Coming Soon |

|

|

|

|

|

|

|

|

| Restore |

Peatlands: Tropical |

256Highly Recommended

|

Remove Carbon |

157

Nature-Based Carbon Removal |

Restore & Manage Ecosystems |

Coming Soon |

|

|

|

|

|

|

|

|

| Deploy |

Perennial Crops |

256Highly Recommended

|

Remove Carbon |

157

Nature-Based Carbon Removal |

Shift Agriculture Practices |

Coming Soon |

|

|

|

|

|

|

|

|

| Improve |

Refrigerant Management |

256Highly Recommended

|

Cut Emissions |

152

Industry, Materials & Waste |

Cut Fugitive Emissions |

Coming Soon |

|

|

|

|

|

|

|

|

| Protect |

Seaweed |

256Highly Recommended

|

Remove Carbon |

157

Nature-Based Carbon Removal |

Restore & Manage Ecosystems |

Coming Soon |

|

|

|

|

|

|

|

|

| Deploy |

Small Hydropower |

256Highly Recommended

|

Cut Emissions |

150

Electricity |

Shift Production |

Coming Soon |

|

|

|

|

|

|

|

|

| Deploy |

Solar Hot Water |

256Highly Recommended

|

Cut Emissions |

148

Buildings |

Shift Energy Sources |

Coming Soon |

|

|

|

|

|

|

|

|

| Improve |

Supply Chain Efficiency |

256Highly Recommended

|

Cut Emissions |

153

Transportation |

Enhance Efficiency |

Coming Soon |

|

|

|

|

|

|

|

|

| Improve |

Truck Efficiency |

256Highly Recommended

|

Cut Emissions |

153

Transportation |

Enhance Efficiency |

Coming Soon |

|

|

|

|

|

|

|

|

| Deploy |

Utility-Scale Solar PV |

256Highly Recommended

|

Cut Emissions |

150

Electricity |

Shift Production |

Coming Soon |

|

|

|

|

|

|

|

|

| Hold |

Virtual Meetings |

256Highly Recommended

|

Cut Emissions |

153

Transportation |

Shift to Alternatives |

Coming Soon |

|

|

|

|

|

|

|

|

| Increase |

Building Deconstruction & Recycling |

257Worthwhile

|

Cut Emissions |

152

Industry, Materials & Waste |

Use Waste as a Resource |

Coming Soon |

|

|

|

|

|

|

|

|

| Restore |

Coastal Wetlands |

257Worthwhile

|

Remove Carbon |

157

Nature-Based Carbon Removal |

Restore & Manage Ecosystems |

Coming Soon |

|

|

|

|

|

|

|

|

| Use |

Cool Roofs |

257Worthwhile

|

Cut Emissions |

150

Electricity |

Enhance Efficiency |

Coming Soon |

|

|

|

|

|

|

|

|

| Increase |

Decentralized Composting |

257Worthwhile

|

Cut Emissions |

152

Industry, Materials & Waste |

Use Waste as a Resource |

Coming Soon |

|

|

|

|

|

|

|

|

| Boost |

Large Herbivore Restoration |

257Worthwhile

|

Remove Carbon |

157

Nature-Based Carbon Removal |

Restore & Manage Ecosystems |

Coming Soon |

|

|

|

|

|

|

|

|

| Deploy |

Ocean Power |

257Worthwhile

|

Cut Emissions |

150

Electricity |

Shift Production |

Coming Soon |

|

|

|

|

|

|

|

|

| Deploy |

Waste to Energy |

257Worthwhile

|

Cut Emissions |

151

Electricity & Industry |

Shift Production |

Coming Soon |

|

|

|

|

|

|

|

|

| Boost |

Whale Restoration |

257Worthwhile

|

Remove Carbon |

157

Nature-Based Carbon Removal |

Restore & Manage Ecosystems |

Coming Soon |

|

|

|

|

|

|

|

|

| Deploy |

Advanced Biofuels |

258Keep Watching

|

Cut Emissions |

153

Transportation |

Electrify Vehicles, Fuel Switching |

Coming Soon |

|

|

|

|

|

|

|

|

| Produce |

Bio Bricks |

258Keep Watching

|

Remove Carbon |

158

Industrial Carbon Removal |

Biomass Carbon Removal & Storage |

Coming Soon |

|

|

|

|

|

|

|

|

| Produce |

Bio Oils |

258Keep Watching

|

Remove Carbon |

158

Industrial Carbon Removal |

Biomass Carbon Removal & Storage |

Coming Soon |

|

|

|

|

|

|

|

|

| Use |

Methane Removal |

258Keep Watching

|

Remove Carbon |

158

Industrial Carbon Removal |

Methane Removal |

Coming Soon |

|

|

|

|

|

|

|

|

| Use |

Nitrous Oxide Removal |

258Keep Watching

|

Remove Carbon |

158

Industrial Carbon Removal |

|

Coming Soon |

|

|

|

|

|

|

|

|

| Deploy |

Ocean Electrochemistry |

258Keep Watching

|

Remove Carbon |

157

Nature-Based Carbon Removal |

Manipulate Biogeochemical Cycles |

Coming Soon |

|

|

|

|

|

|

|

|

| Improve |

Routing & Logistics |

258Keep Watching

|

|

153

Transportation |

Enhance Efficiency |

Coming Soon |

|

|

|

|

|

|

|

|

| Deploy |

Sustainable Aviation Fuel |

258Keep Watching

|

Cut Emissions |

153

Transportation |

Fuel Switching |

Coming Soon |

|

|

|

|

|

|

|

|

| Deploy |

Artificial Upwelling |

259Not Recommended

|

Remove Carbon |

157

Nature-Based Carbon Removal |

Manipulate Biogeochemical Cycles |

Coming Soon |

|

|

|

|

|

|

|

|

| Increase |

Livestock Grazing |

259Not Recommended

|

Remove Carbon |

157

Nature-Based Carbon Removal |

Shift Agriculture Practices |

Coming Soon |

|

|

|

|

|

|

|

|