Climate Solutions at Work

While engineering jobs range from software to mechanical, all engineers have one thing in common: you take a product vision and turn it into a reality. Engineers are both creative and technical. As a builder, you can incorporate climate as a key component of product assembly, integrating it into how you code and manufacture. Engineers can help make sustainability the industry standard by constructing products that use less energy and are made of low-carbon materials.

Please note that this guide is meant to be broad, and actions may be more or less applicable depending on the scope of your role, your company, and the industry in which it operates. We recognize that engineering roles may overlap with other product development roles; make sure to also check out the Product Management and Design action guides for more ideas. We encourage you to explore the actions in all of the guides to see which are most relevant to you!

Lastly, have you used this or any of our Job Function Action Guides to make your job a climate job? If so, we want to hear about it! We encourage you to share your story with us by emailing labs@drawdown.org

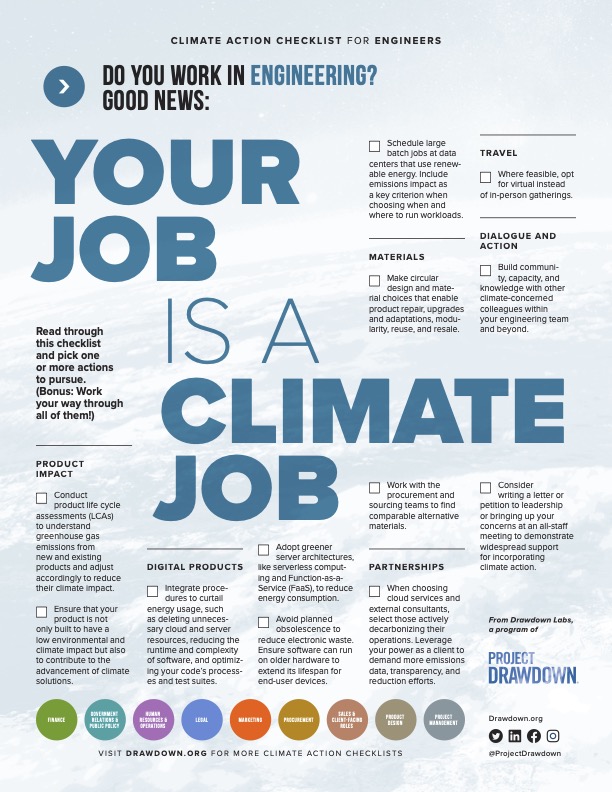

To make your engineering job a climate job:

Measure product impact

- Consider how your product contributes to or mitigates the climate crisis, as well as other environmental impacts. Not only is your product built to have a low environmental and climate impact, but does it also contribute to the advancement of climate solutions? (Learn more about Drawdown Solutions for inspiration.)

- Conduct product life cycle assessments (LCAs) with the sustainability, procurement, design, manufacturing, and other teams to understand and mitigate the greenhouse gas emissions impact of new and existing products. (LCAs are critical for understanding and reducing emissions from products, as they can vary greatly across the supply chain and industries.)

- Collaborate with data teams to identify the most appropriate technology for product LCAs, allowing you and your team to find sustainable alternatives and track product usage.

- Ensure data transparency throughout the product development process and communicate to your colleagues the potential long-term consequences of engineering decisions.

- Determine your product’s "hot spots" – the components or usage that have the greatest potential to contribute to global warming, energy consumption, and other environmental impacts. For example, for some products, emissions resulting from manufacturing are much higher than emissions resulting from usage.

- Document any improvements and setbacks between product generations so that the impact of specific design changes can be tracked, evaluated, and improved on.

Assess digital products

Energy efficiency

- Integrate energy-saving procedures, such as deleting unnecessary or unused cloud and server resources, reducing software runtime and complexity, and optimizing code processes and test suites.

- Monitor real-time power consumption when launching a product to understand the gaps between the design choices and actual energy profiles, and adjust accordingly.

Hardware efficiency

- Adopt greener server architectures, such as serverless computing and Function-as-a-Service (FaaS), to reduce energy consumption as well as save money by reducing the need for cooling, real estate, and hardware purchasing and maintenance. (Cloud or Function-as-a-Service environments can fit more work on the same hardware because they average the loadout from many workloads – the more private a set of hardware is, the more it sits idle, consuming power.)

- Avoid planned obsolescence to reduce electronic waste (e-waste). (The world generated 53.6 million metric tons of e-waste in 2019!)

- Ensure that software can run on older hardware to extend the use of end-user devices.

- Avoid unused or underutilized capabilities and maximize hardware utilization to reduce embodied carbon – greenhouse gas emissions stemming from the life cycle of products, from raw material extraction, manufacturing, and through to end-of-life.

Carbon-aware computing

- Schedule large batch jobs at data centers that use renewable energy.

- When it comes to energy efficiency, keep timing and geographic context in mind. Consider that the carbon intensity of the grid varies throughout the day and across regions. (See Google’s Carbon Free Energy 24/7 initiative and work to shift demand to when the grid is cleaner.)

- If your company employs a multi-cloud strategy, consider emissions in addition to pricing and performance when deciding when and where to run workloads.

Looking for more ideas on how to develop software sustainably? Check out the Green Software Foundation’s official training!

Engineering economics

- If you’re in a leadership position and your team uses a chargeback model to allocate and hold engineers accountable for costs, consider instituting a similar model for carbon emissions to ensure engineers are not only staying within your team’s or company’s financial budget but also their carbon budget. (See how Microsoft uses a global carbon fee to hold its business units financially accountable for emissions.)

- If you’re an individual contributor, gather data and present the carbon-equivalent savings numbers. Two options with similar costs will often have significant differences in associated emissions, and this information can influence key decision makers.

Assess physical products

Prototyping

- Consider using virtual twins for prototyping, which can reduce design and development time, raw material consumption, and thus a product's carbon emissions.

Minimizing impact of materials

- Work with internal and external partners, as well as experts in the circular economy and sustainable materials, to evaluate all material and design options.

- Assess the potential benefits and consequences of different materials for your product – beyond just greenhouse gas emissions – to consider other potentially harmful effects on people and the planet, such as water use, biodiversity impacts, and chemical pollution.

- Consult experts on the potential upstream (e.g., manufacturing) and downstream (e.g., packaging disposal) effects to ensure that they are taken into account early in the design process.

- Design with less – also known as dematerialization – by reducing content and using fewer and lighter materials and packaging.

- Choose circular design and material options that enable product repair (like Patagonia), upgrades and adaptations, modularity (like Fairphone), reuse, and resale. Avoid planned obsolescence and prioritize durability.

- If designing for take-back and recycling, keep in mind the complexities and ambiguity surrounding recycling. For more information, see this guidance.

- Collaborate with the procurement and sourcing teams to identify sufficient alternative materials. Take a targeted approach, first replacing the most harmful materials or ingredients that you use in large quantities. Use verification tests to show comparable performance.

- Bring in experts and use other resources to educate your team on sourcing "rules of thumb." For example, across various raw materials, there are global deforestation hotspots that your company should generally avoid to reduce its contribution to ecosystem destruction. (Consult resources like Climate TRACE’s emissions data comparison tool and Project Drawdown’s Drawdown Roadmap.)

Many of the above actions will most likely be dependent on your company's overall business model – try to find more information on your company's operational capabilities that are required to support circular design choices.

Evaluate partnerships

- When selecting cloud services and collaborating with external designers, scientists, or other consultants, prioritize those that are actively decarbonizing their operations and have science-based targets across Scopes 1, 2, and 3.

- If your company is a large and/or long-term customer, use that leverage to demand more emissions data, transparency, and reduction efforts from your cloud provider.

Reassess team travel

- Reduce carbon-intensive business travel for you and your team by opting for virtual meetings. If you can, avoid flying and instead take a train or use another mode of transportation that emits fewer emissions.

Foster dialogue and action

- Build capacity and knowledge by connecting with other engineers – and other colleagues in your organization. Come together to brainstorm climate action steps (check out Project Drawdown's Discover page for ideas!), share best practices, and raise your collective concern at team and all-staff meetings.

Ready to take action? Here are some questions and ideas to help you get started:

Take stock.

Identify your company’s corporate sustainability and climate commitments, if any.

- Are these goals related to those of the engineering team?

- Can you incorporate the actions listed above into your company, team, or individual performance goals?

- Does your company have a goal to reduce Scope 3 emissions (emissions from the use of its products)?

- Is the product team pursuing low-carbon and circular design principles, specifying sustainable materials, and/or incorporating other criteria into product development?

- If your company sells digital products, is it actively working with cloud providers and finding ways to increase energy efficiency?

- Is there a mandate or incentive in place for leadership to incorporate sustainability value commitments into all new product development?

- Can you start or join a green team or a climate employee resource group?

Make needed changes or reach out to someone else who can.

- What kind of decision-making authority do you have? Can you carry out these actions on your own, or do you need to consult with a manager or director?

- Are those with decision-making authority already on board with climate action? Is there anyone you might be able to engage and influence?

Test the waters by discussing your own interest in climate action with trusted colleagues and gauging their reactions. Consult power-mapping tools for help.

You don’t have to do it alone.

Find others in your department who are climate-concerned. Join forces to demonstrate widespread support for incorporating climate action into engineering and across the organization. Consider writing a letter or petition to leadership or bringing up your concerns at an all-staff meeting.

Need help making the business case?

Companies that create sustainable products benefit from increased compliance, increased revenue, lower costs, and improved customer and employee relationships. Engineers who create products that consume less energy save their companies money (see this case study on Etsy's transition to a green cloud).

Sustainable products are also important for attracting customers and investors, both of whom prioritize sustainability in their decision-making. In 2022, three out of five customers said “socially responsible or sustainable products made up at least half of their last purchases,” and the same ratio of investors said they take sustainability into account when building their portfolios.

Employees are also increasingly placing a premium on sustainability. Almost 70% of workers in the United States consider a company's environmental record when applying for a job, and those under 30 are even more adamant about working for companies with good environmental records with 93% agreeing that the more socially and environmentally responsible their company becomes, the more "motivated and loyal their employees will be."

Resources

Software

Circularity and materials

- The Ellen MacArthur Foundation hosts many resources on circular economy for different industries, including plastics, food, and fashion.

- ScienceDirect has a large library of sustainable design resources on green materials and manufacturing processes.

- Climate TRACE provides granular emissions data across sectors to help you make more informed decisions around sourcing and hold suppliers accountable.

- The Carbon Leadership Forum hosts a library of resources to help engineers, designers, and others reduce embodied carbon in materials.

- MEP 2040 is a collective initiative mechanical, electrical, and plumbing systems engineers and designers can sign onto to commit to reducing embodied carbon emissions associated with MEP systems.

Design

Climate justice

Everyone has a role to play

The Drawdown Labs Job Function Action Guides will help employees understand how their roles are critical in addressing the climate crisis, as well as implement high-impact solutions and navigate key considerations for taking action inside the workplace.

Partnerships

and Community

Affairs

Please note: This graphic is illustrative of how different teams across a company must work together to achieve strong climate action. We encourage you to examine your organization’s own unique structure to determine how to best coordinate and integrate climate action across functions.